Floor Mounted Auto Vacuum Loader

Categories : Loaders and Conveyors

The separated design of a blower and a suction hopper with mighty horsepower is suitable for long distance conveying. The flexible combination of one blower with one suction hopper up to four suction hoppers can help you to save space and equipment investment cost. That also keeps your resin away the pollution and extend suction points easily for future need. TA series Easy use by a quiet and powerful induction motor. The motor cabinet can be placed on the floor for convenient operation and the suction hopper on the hopper dryer for easy installation. TB series Use the same commutator motor as the BC series, and separate motor cabinet and suction hopper design as the TA and TC series. Combine the advantages of the hopper mounted and floor mounted loaders. TC series The blowers are belt-driven that are the best choice for silent operation. Patented Optional Parts Vortex Cyclone (VC): Works with any auto loaders to stop the regrinded resin from discharging to the surrounding area. Filter Set: s optional equipment from YANN BANG is perfect for dust-free of indoor working place. To do the filter routine maintenance is so easy without dirtying your hands and place. Unload the filter set without opening the cover until move to the please you want to clean. Auto Dust Cleaner: Saves your time and labor. No need to clean your filter anymore. The Auto Dust Cleaner is designed to install upon the filter of the loader. Set the timer and it cleans your filter routinely.

Powder Vacuum Loader

Categories : Loaders and Conveyors

Powder Vacuum Loader It’s “trend of the time” by using recycled material in the manufacturing process and absolutely necessary. Considering of create much dust after granulating the recycled material, re-manufacturing with dust to cause raw material waste and burned the motor. To increase the operator health problem and environment pollution. The system composes by suction hopper of powder & floor type vacuum loader with patented vortex cyclone and air filter double pieces. It’s great idea to prevent the dust leakage and air pollution under

Central Safety Filters

Categories : Loaders and Conveyors

SCSF series central safety filter in central loading system adopts large dust collector to filter dust and small impurities in material so can effectively protect blower and prolong its service life. Self-cleaning function realize the effective cleaning of the filter by set-up auto timer, which can reduce manual clean times. Equipped with vacuum breaking valve to not only protect the blower, but also accelerate conveying and loading speed.

2-in-1 Conveying Dryer (CD)

Categories : Dryers and Dehumidifiers For Plastic Materials

Hopper dryer combine vacuum loader is perfect to move anywhere for your need. A stainless insulated hopper dryer with dual layer to help drying better and faster. Save more energy and increase higher efficiency. A vacuum loader automatically supplies dried resin to avoid the shortage of material during production. Installed pipe-clean device (Taiwan Pat:M299801) and closed-loop can prevent the moisture return, static electricity and resin pollution inside the pipe for better quality. Patented Heat-recycler (Taiwan Pat:226245;China Pat:01258213.1) can save your energy, increase drying and decrease the pollution of hot air and dust. Installed weekly timer and safety protectors can save your labor cost and protect operators in better working environment. Only one control unit is convenient for you to monitor all suction points. Able to extend suction points up to four as 1 to 4 small central conveying system to supply resin for raw material areas and numerous molding machines. Save your equipment cost and space without extra spend.

Tube Loader (AL)

Categories : Loaders and Conveyors

Stainless unique design is dust-free and clean –free for optics users perfectly. Light weight and compact size can be directly mounted to any vessel and machine without purchasing another vacuum loader. Save your cost and space. By using compress air efficient venture draws resin from material tank. No motor and low noise is perfect for clean room, indoor work, and electronics and medical users. Good for small batch and various kinds of production, high stability, high efficient supply to prevent moisture return of resin. Glass sight window gives a clear view of loading and safety protectors to help operators working more efficiently.

Separate Vacuum Hopper Loaders SAL-UG

Categories : Loaders and Conveyors

SAL-UG series separate-vacuum hopper loaders are based on the established design and now feature more attractive appearance, better performance, and improved ease of operation. The whole range comprises of seven models equipped with vacuum blower from 1 to 15 HP. Economy models can be offered on request.

Hopper Mounted Auto Vacuum Loader

Categories : Loaders and Conveyors

BC series Use high speed, powerful, single phase commutator motor and is the smallest and the most economical loader in our range. Compact size, light weight, low noise, easy operation and installation, suit to convey one kind of resin or material, can install upon a hopper dryer or molding machine directly. It is ideal for small machines. BL series Easy use by the three phase powerful induction motor. Suitable for medium to large size machines, such as extrusion molding machine.

“Standard” Separate-vacuum Hopper Loaders - SAL-G

Categories : Loaders and Conveyors

Stainless steel hopper and with motor overload protection. Audible material shortage alarm. Independent filter designed for easy maintenance. SAL-700G/810G/820G/830G are equipped with the RS485 communication port. SAL-810G/820G/830G can control the proportional valve SPV-U and shut-off suction box independently. SAL-900G/G2 has two-stage conveying function.

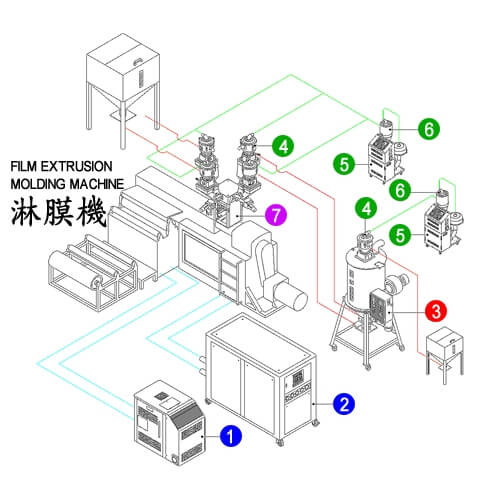

Film Extrusion Molding Machine Auxiliary Solutions

Categories : Assembly Systems

We have a wide range of auxiliary equipment for film extrusion molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place

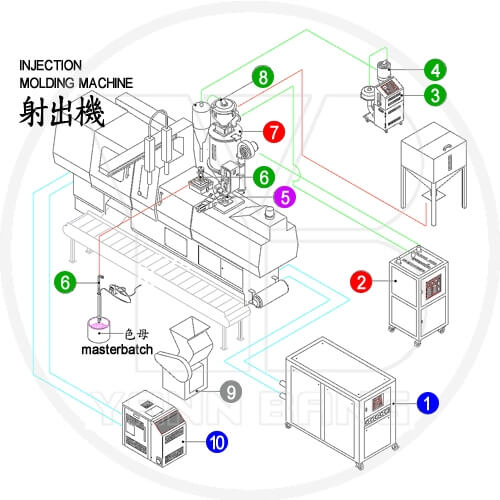

Injection Molding Machine Plastic Auxiliary Solutions

Categories : Vertical Injection Molding Machines

YANN BANG offers a wide range of auxiliary equipment specificaly for injection molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place

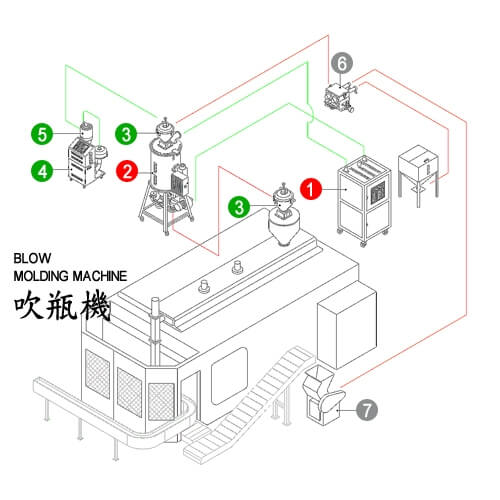

Blow Molding Machine Plastic Auxiliary Solutions

Categories : Extrusion Blow Molding Machines

For blow molding mechines, we can supply a wide variety of auxiliary equipment, e.g.: hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place

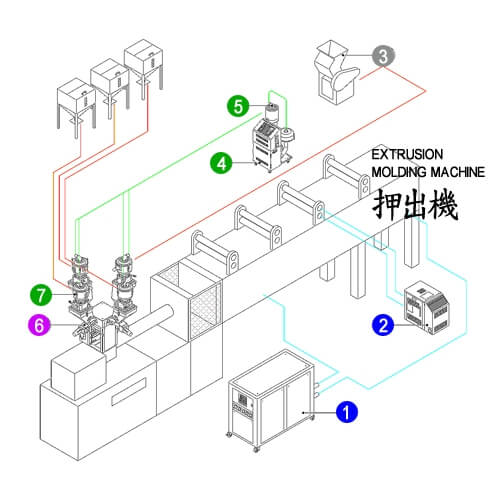

Extrusion Molding Machine Plastic Auxiliary Solutions

Categories : Assembly Systems

We are capable of offerring a wide range of auxiliary equipment specificaly for extrusion molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place